App Guide for Quality Control

Quality control is crucial in helping users to find out whether the vendor’s goods are acceptable or not, depending on the items’ quality. Quality control is carried out through control plans, which allow to automatically create inspection orders whenever a loading has been made If an item doesn’t pass the quality control it is automatically transferred to the non-compliant warehouse. The quality control Officer will have his own page to check the inspection orders, which will be automatically updated by the system each time a loading with a quality control submitted item has been made

1. Setup App Quality Control

Set the required fields in the SETUP section:

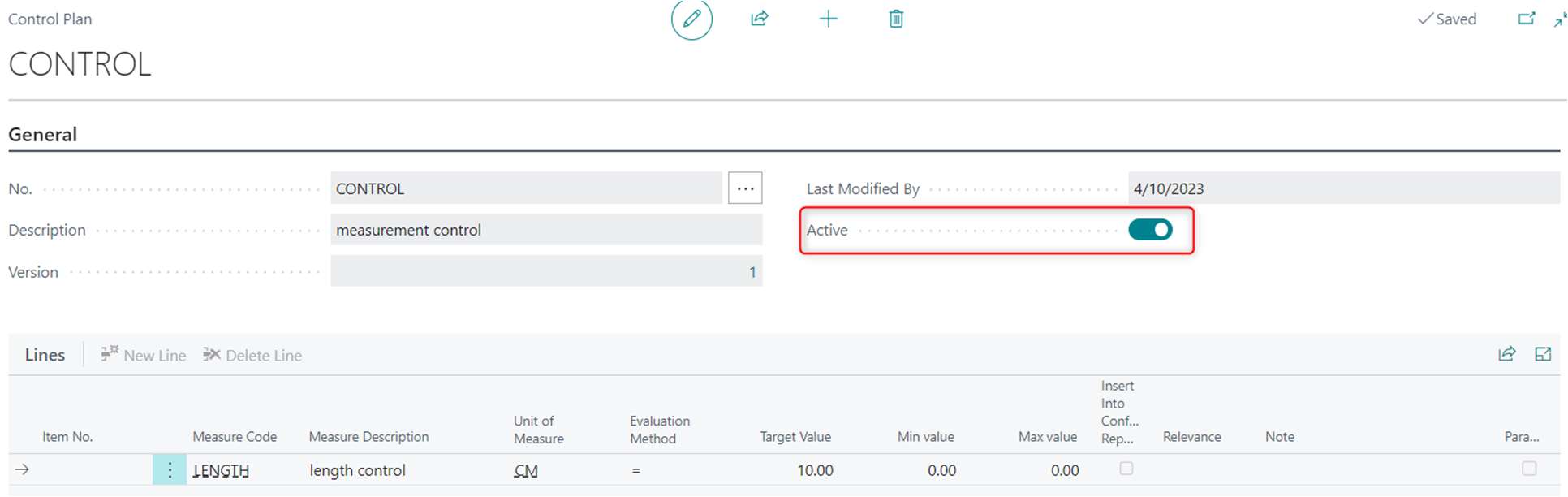

Create a control plan to determine which parameters the system has to check on to verify the item’s conformity: a control plan can be designed to be assigned to multiple articles, if they have equal characteristics; otherwise, each item can have its own control plan.

A control plan can be revised through time, since the app allows to create multiple versions of the same plan, allowing the user to track changes through time.

After identifying the number and description of the control plan, in the Lines section it is possible to define the control type one wants to perform by choosing among different evaluation methods and entering the related parameters (e.g. the target value).

The Active flag validates the control plan, which can then be selectable for an item.

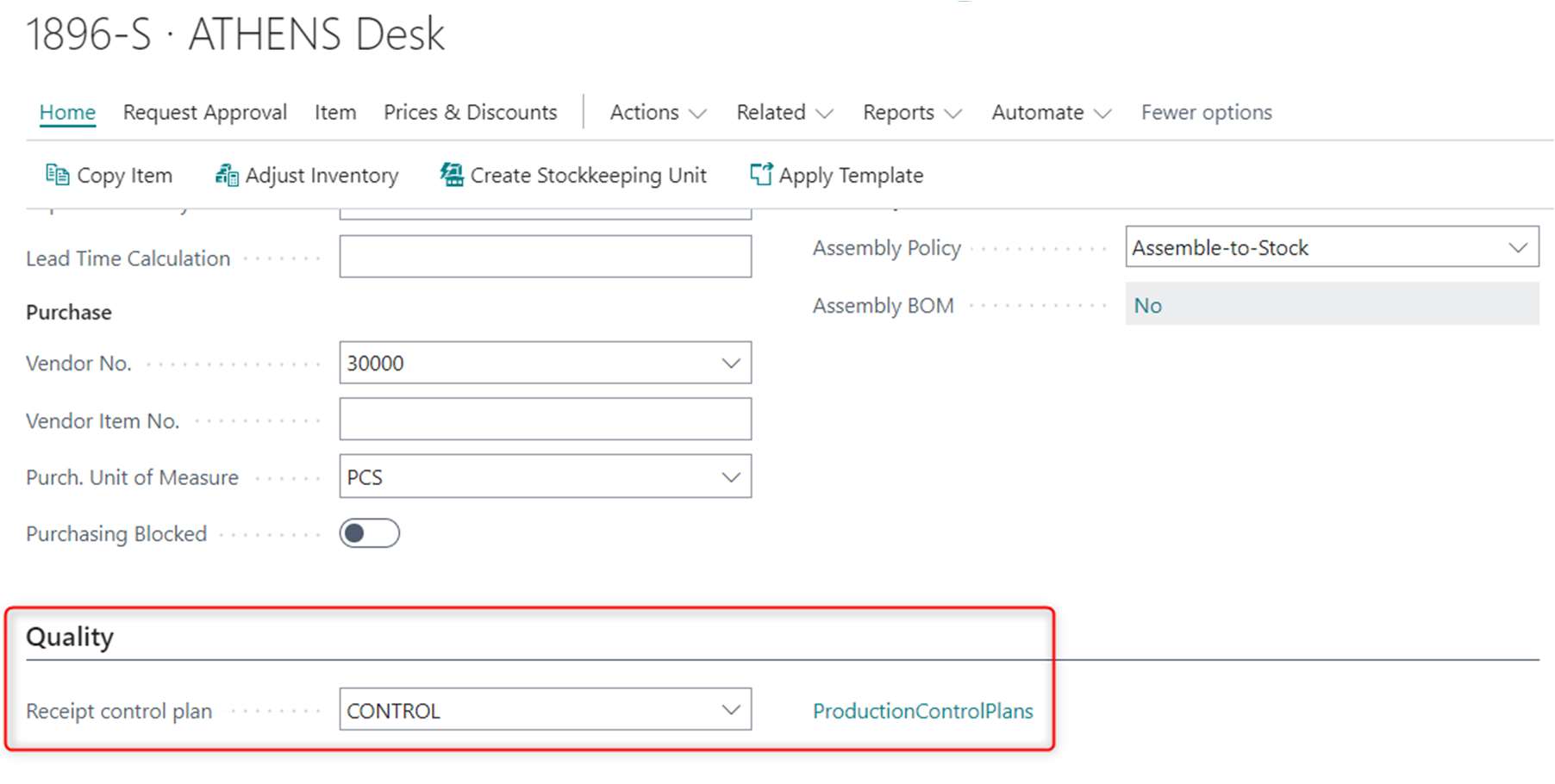

1.1 Quality Section

In the Quality section of an item’s page the more suitable control plan can be picked among the ones created.

Every time the item is loaded in the warehouse from a purchase order, the system will automatically generate an inspection order for it It is possible to apply Free-Pass to vendors, a process that automatically determines the items’ conformity, according to a certain quality-compliant purchase orders threshold and a time period set by the user: the Free-Pass is always resettable in the inspection order, if the user wants to manually control for the item’s conformity.

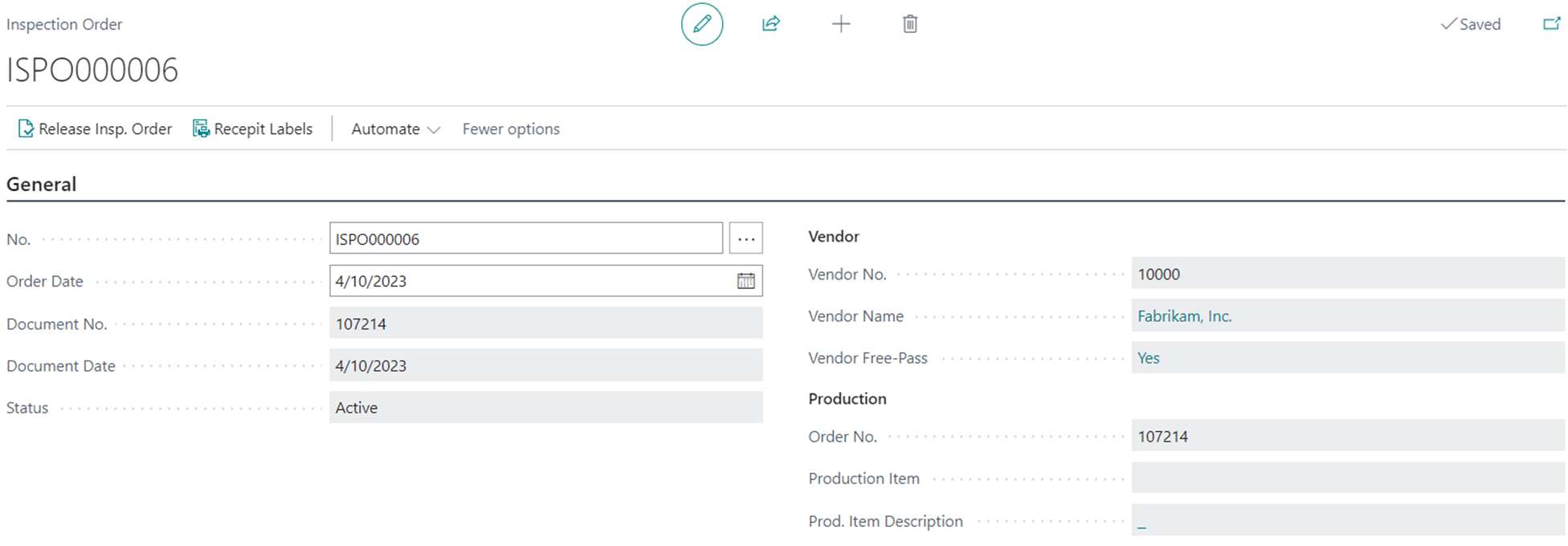

After a loading with at least one quality control submitted item has been made, the system will automatically generate an inspection order. An inspection order has header and lines fields: some of them are automatically filled by the system, according to the Purchase order data and the Control plan data.

2. Quality Control: Process

In the header fields are present the No. and Order date of the inspection order, Document No. of the purchase order and its Document Date, while the Status field tells if the order is still open (Active) or closed (Closed); the Vendor No. and Name are present, with the indication whether the Vendor as a Free-Pass or not.

Section

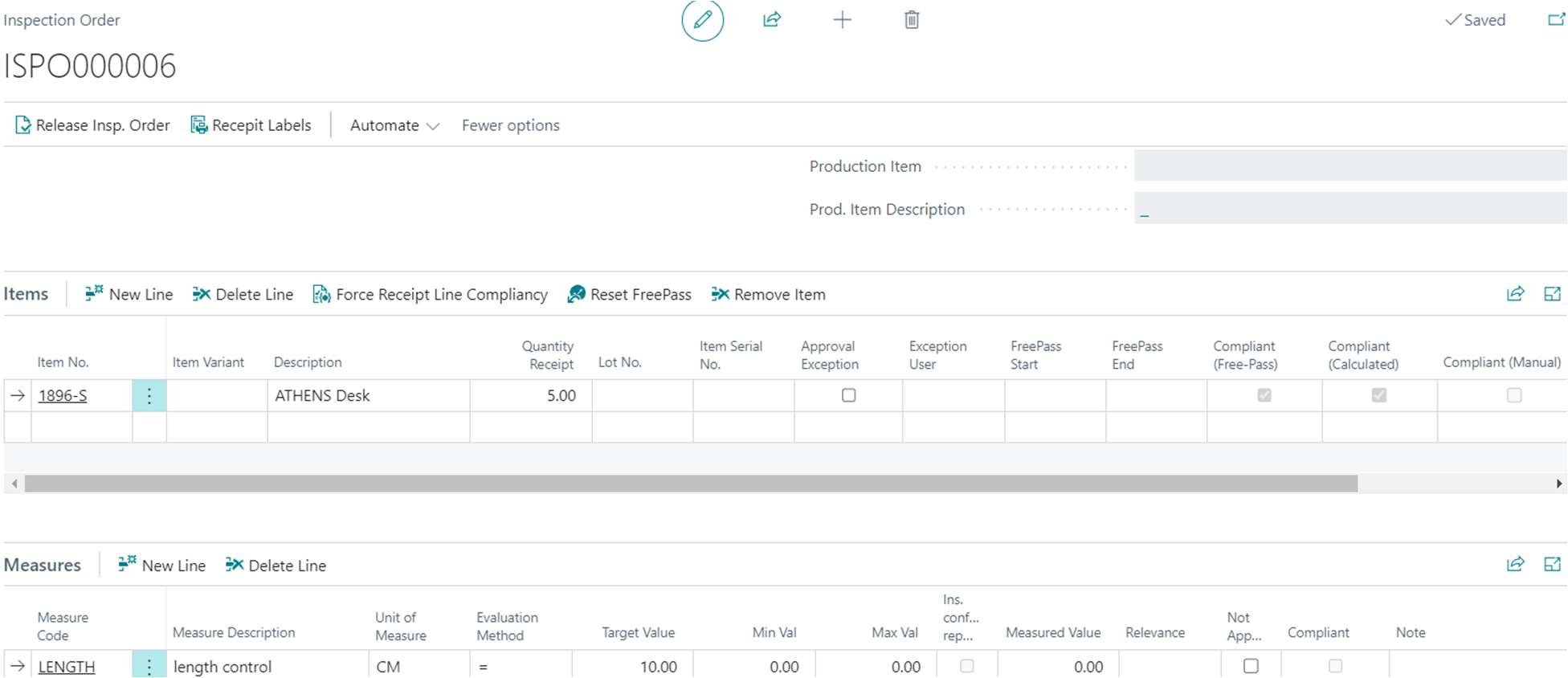

In the ITEMS section each row presents the item from the purchase order, with the Related Document No.; if the item is lot-managed, there will be several lines, one for each lot: the control has to be done for each row in the Measures section

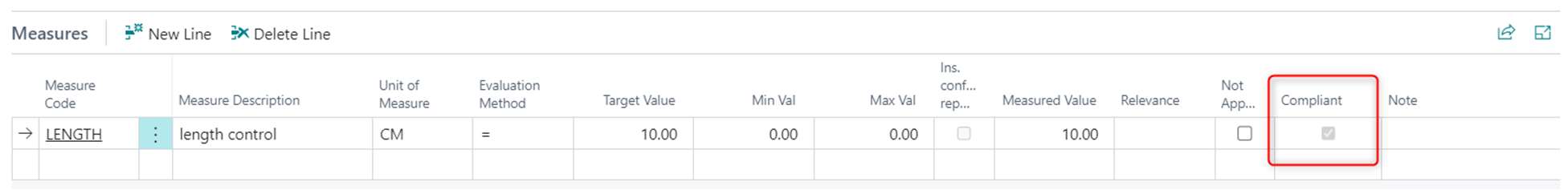

In the Measures section there are the same parameters of the quality control plan associated to the item: insert the Measured Value as the actual measurements observed on the item

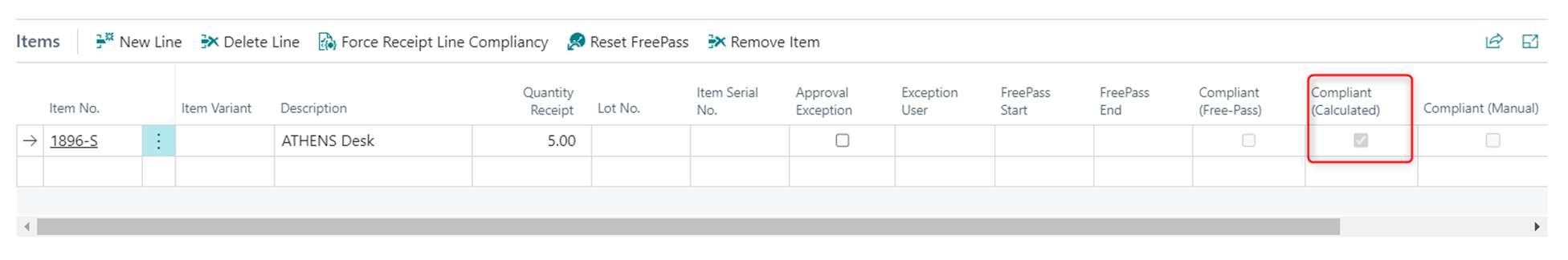

The system will automatically check if it satisfies the Evaluation method with the Related Target value: if yes, the system will insert the flag in the Compliant field

When each row in the Measures section have obtained the Compliant flag, the item is compliant and the same flag will be inserted in the Items section:

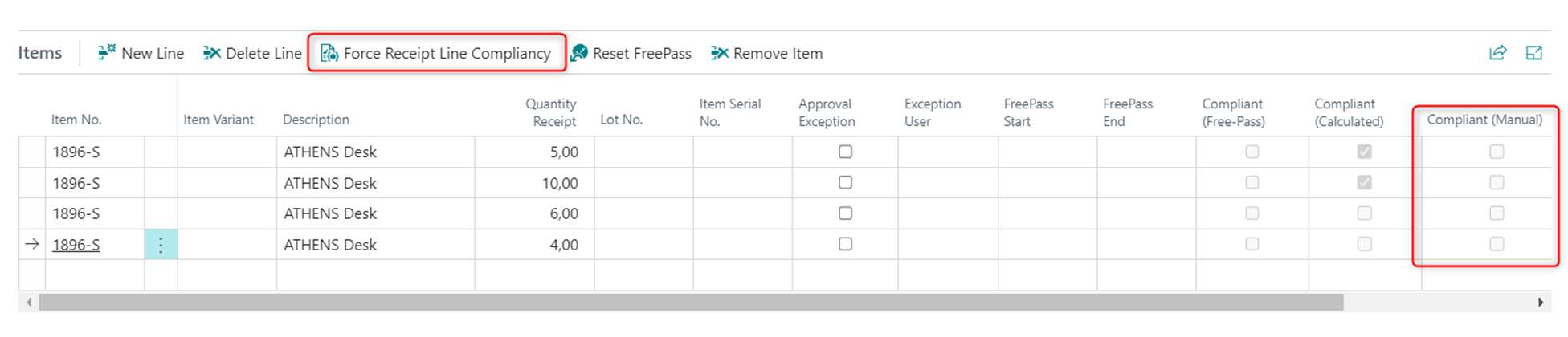

If one or more of the items were verified as compliant, Force Receipt Line Compliancy allows to state the conformity of the other items as well without entering their measures.

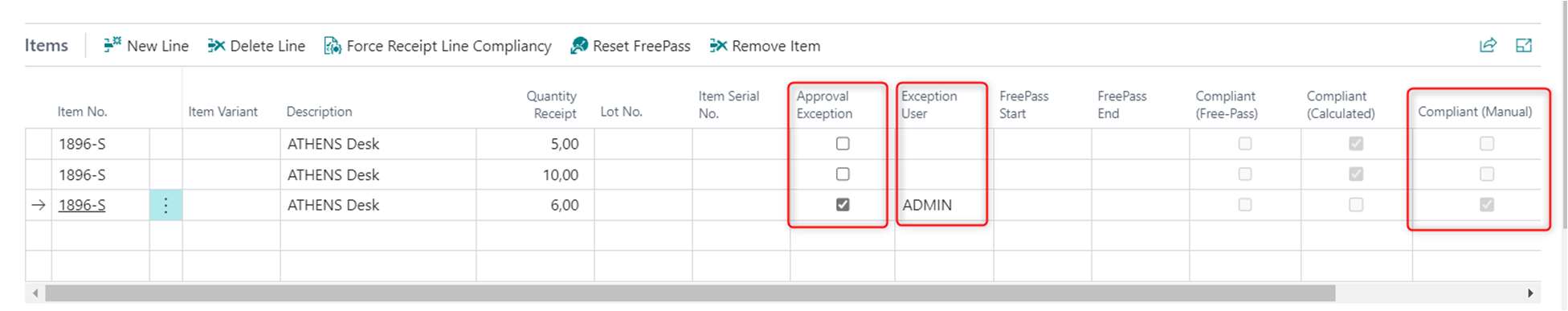

The user is also able to state that an item is compliant with exception, meaning that an item is manually accepted as conform even though some measurements of the item are not sufficient to pass the quality control

For traceability reasons the name of the user will be automatically posted.

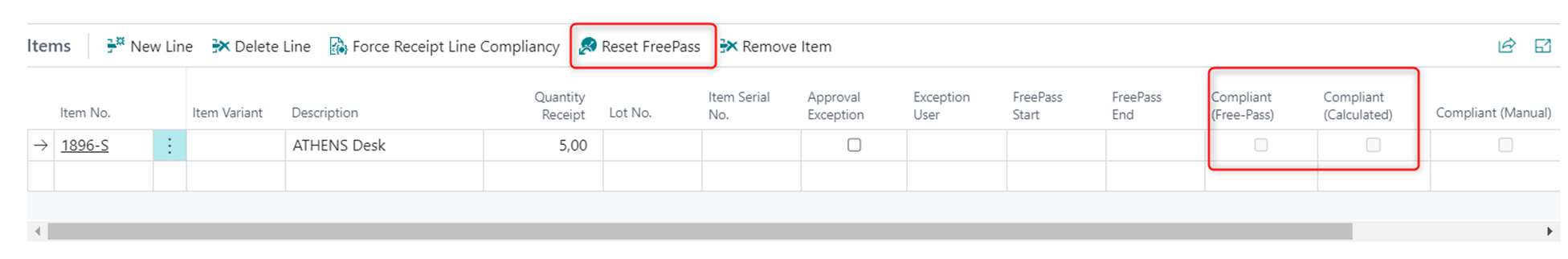

Even with e Free-Pass vendor, the user is able to inspect the order, by choosing Reset FreePass and manually inserting the inspected measurements.

After releasing the inspection order, if an item has not obtained a compliant flag in the inspection order, the system will automatically transfer it from the loading warehouse to the non-conformal warehouse.