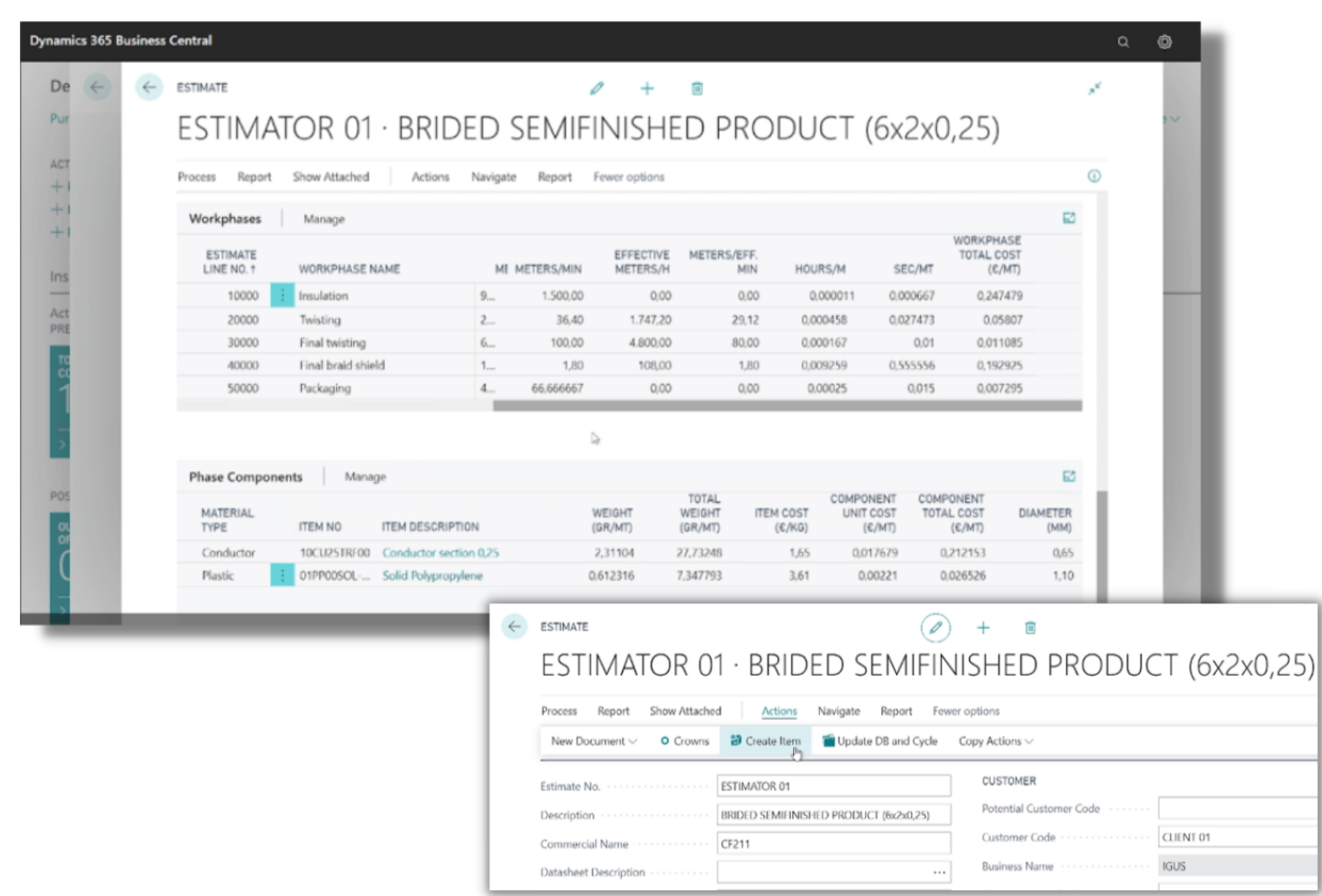

ESTIMATOR

Estimate components cost

Managing specific parameters such as the weight of the cable, of the copper and the technical data (temperature, voltage exercise, diameter).

Estimate costs of processing steps

Massive update of quotes

You can also straightly link the reference norms to each quote and define the crowns relating to the cable structure.

Create the cable item

With the indication of the bill of materials and routings; any change made in the estimator will be updated on the item of the finished cable.

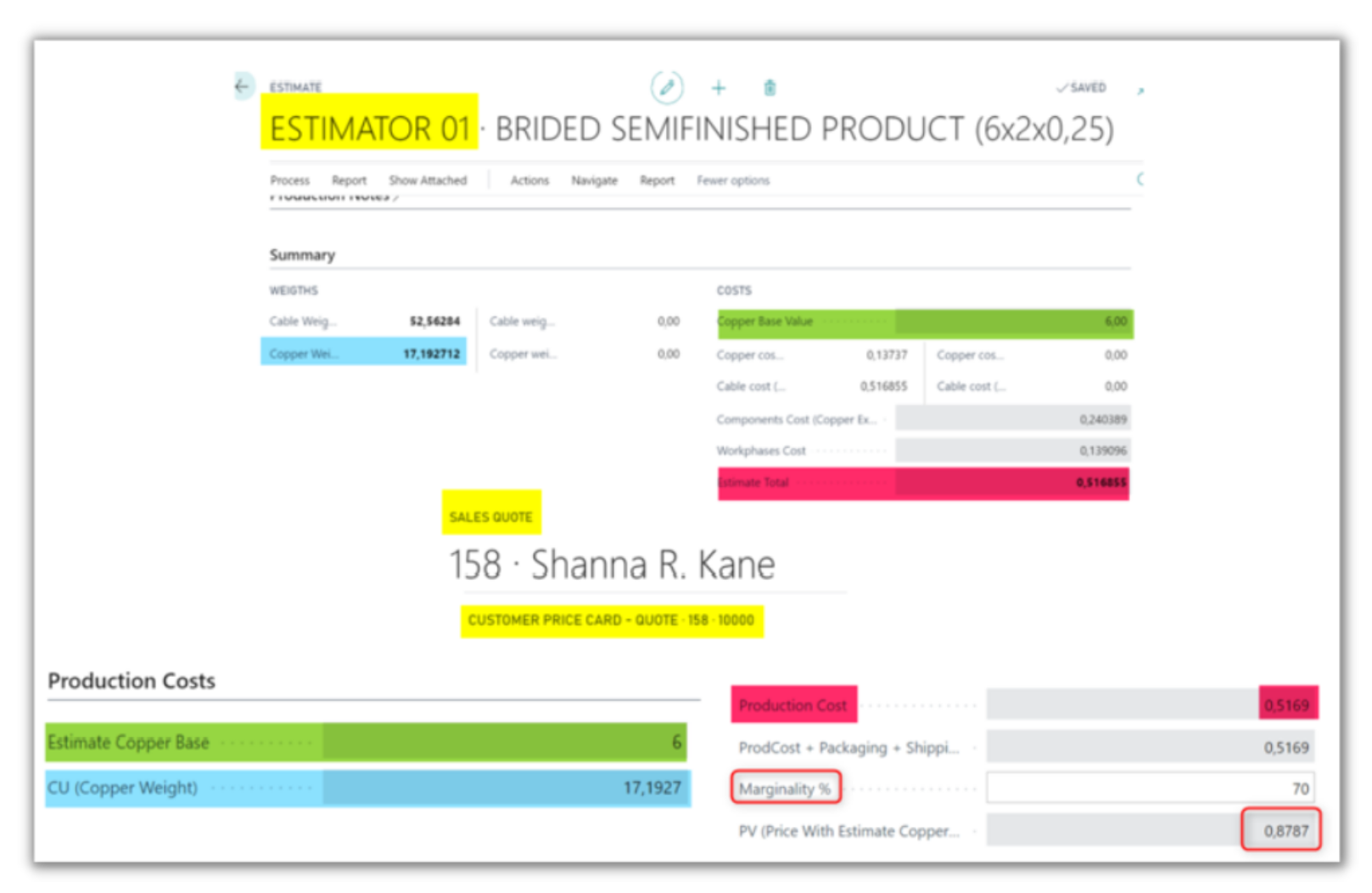

CABLE PRICE ENGINE

Track costs

The system keeps track of every production cost related to:

- final cable

- packaging

- transport

Control on margins

Automatically calculated by the system simply setting the desired margin.

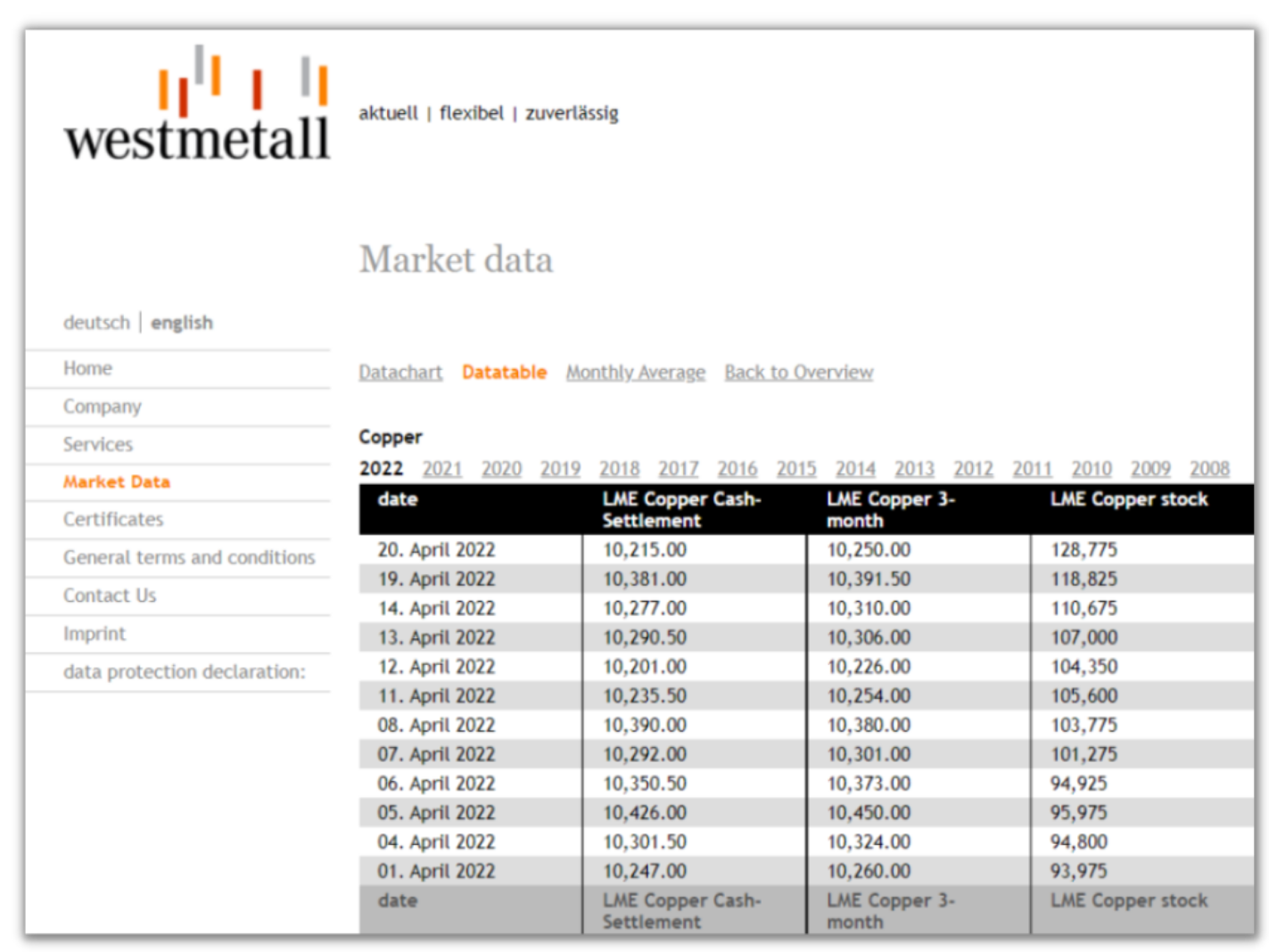

INTEGRATION WITH THE COPPER EXCHANGE

Daily import of price of copper

Through the Westmetall.com website.

Track of changing in margin

The system tracks changes in margins as a result of variable fluctuations in copper and/or production costs.

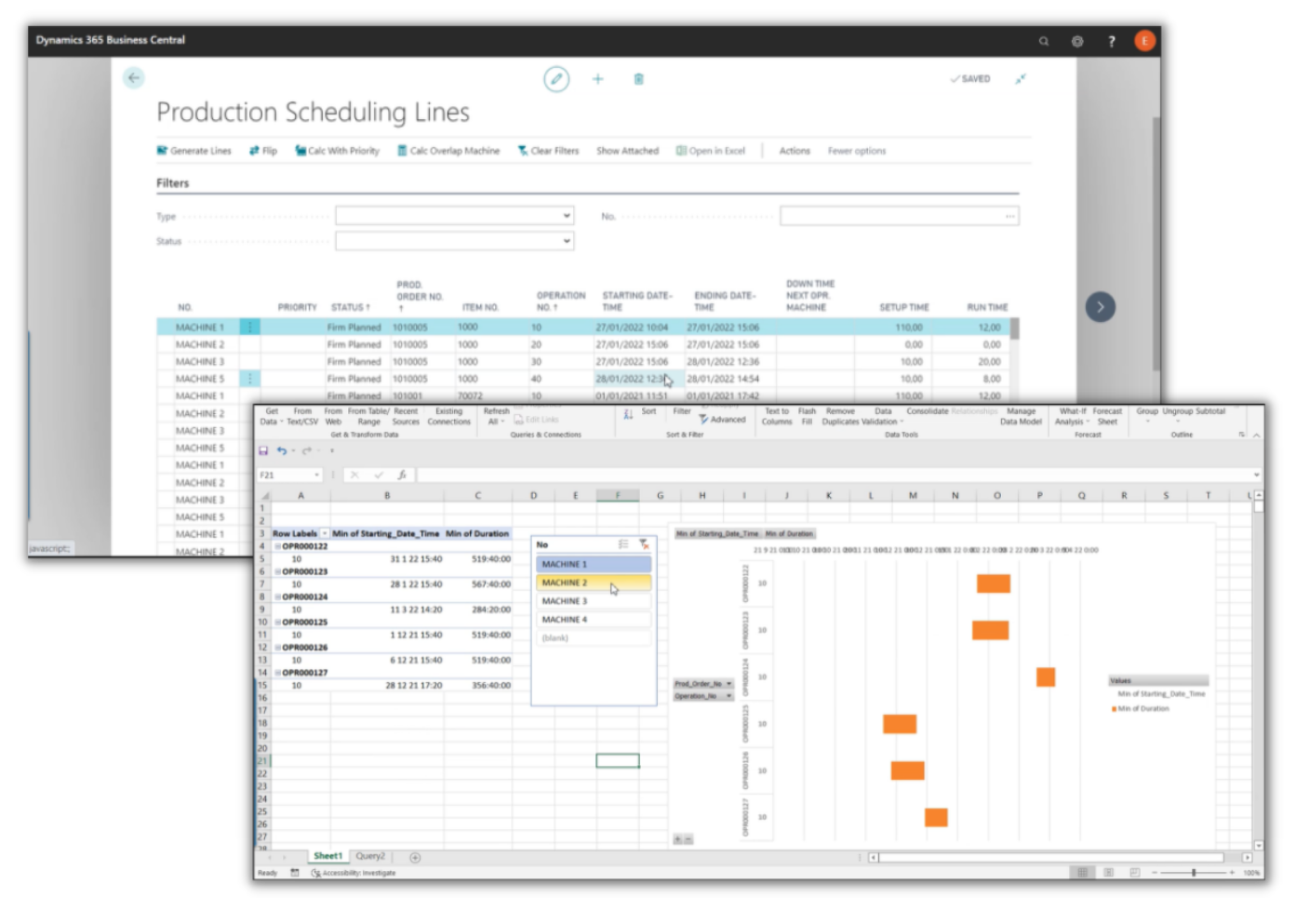

SIMULATION ENVIRONMENT

Schedule your production orders in a Simulated Environment

Launch your Production Planning only when data on your sull'ERP massimizzano i risultati

- Check the downtime and the overlap between two consecutive routing steps

- Schedule on Cascade the production plan

- Embed the integration with excel where you can view the Gantt Diagram of the production steps

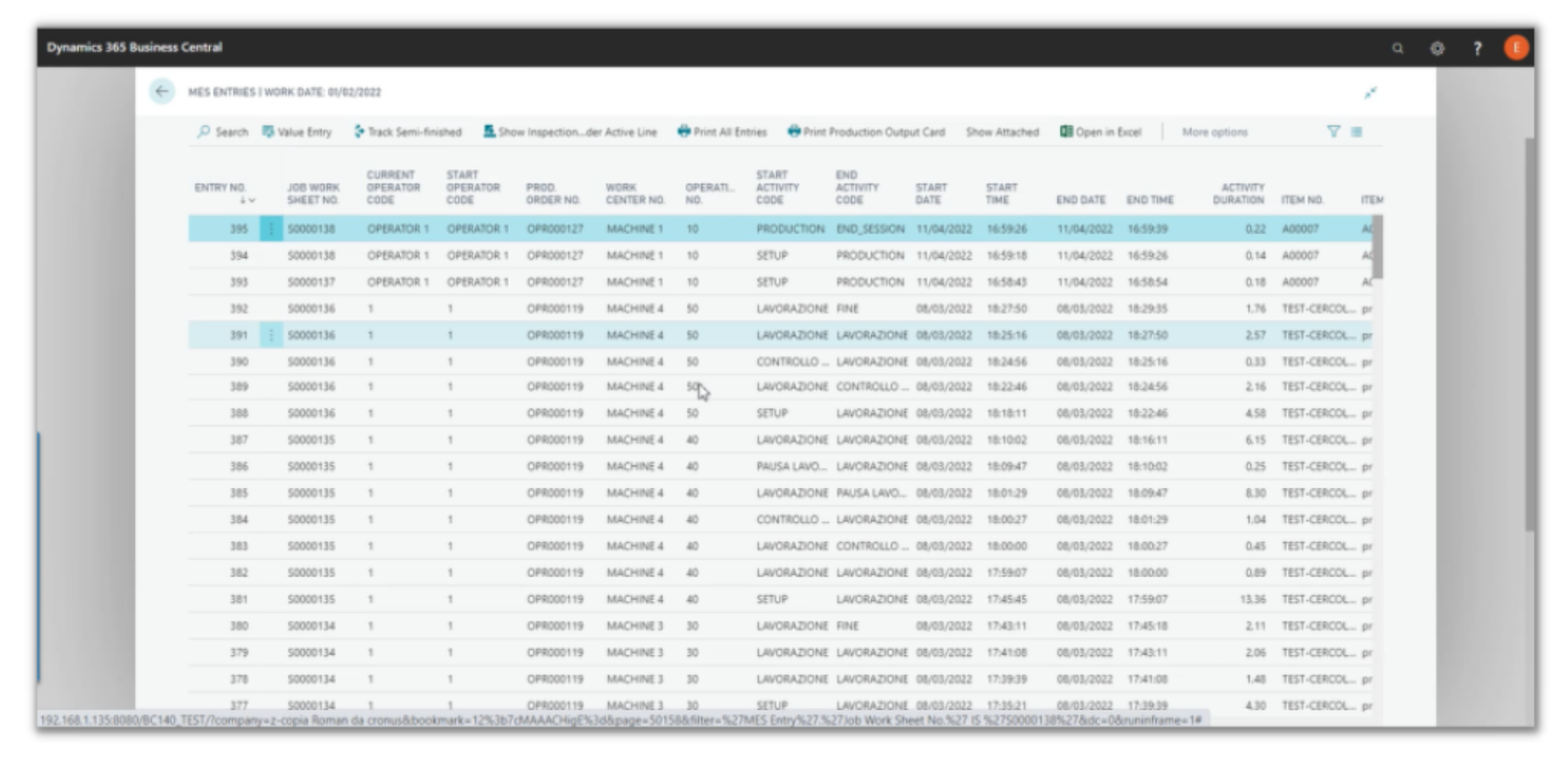

MES

Real time production monitoring

- Define the mandatory data that an operator must enter in order to be able to continue in the expected flow of activity.

- record automatically the costs related to the processing time and setup.

- automatically generate production output and consumption

Integration with the Corporate Information System

With Eliot 4.0, The Industrial architecture of Euris, that enable the bi-directional communication between the production line and the corporate information system.

Real Time data

Have real-time production progress and machine performance data (KPIs like OEE)

Automate the production

Automatically send Production Orders from the ERP/MES/SCHEDULER to the machines

Configure alert

Trigger alarms and notifications against certain conditions and events

Analytics dashboard

Provide the Management with analysis dashboards and implement predictive maintenance

Finalization production order

Automatically advance the time and quantity produced in production orders

OEE (Overall Equipment Effectiveness) Panel Display

Displays in real time the total effectiveness of each plant and highlights the important factors for manufacturing production:

current machining status bar

machine downtime signals

scrap details

Allow, through the collection and historicization of production metrics, to teach to the component of Machine Learning in Eliot4.0, based on Neural Networks for detection faults and predictive maintenance in order to estimate any issues to avoid the machine’s block.